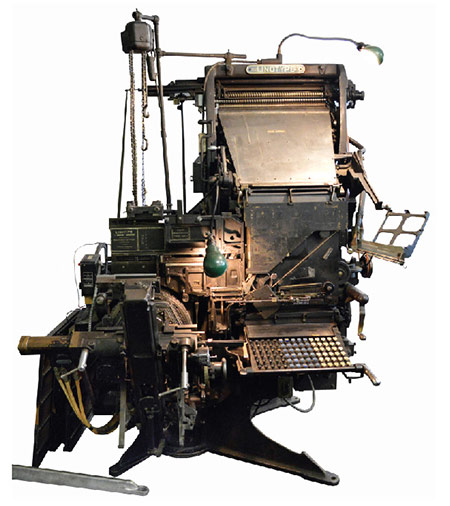

linotype machine

Description of the Mergenthaler Linotype used at the Covington Virginian newspaper operation in Covington, Virginia

The Mergenthaler Linotype was used for hot type printing. The machine was capable of making 8pt and 14pt type.

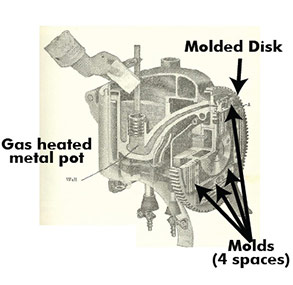

The linotype made type in two different ways, by an operator and with Teletype Setter (TTS) tape. The TTS operator would type on the machine just like a typewriter and the TTS tape would then be fed into the linotype. The TTS machine would punch holes in the tape, which was a code, the opposite of Morse code. The type was created with brass letters, numerals and symbols which were mechanically dropped into the machine. The linotype held a large piece of lead called a pig. The pig was heated into liquid lead. The machine used natural gas as its heat source. As the type was created with the hot lead, it came out of the machine exactly to fit one column. It could also make up to a three column 14pt headline. Larger headlines were made with a Ludlow machine.

- From type written document provided by Mary Ann Beirne August, 2019.

WHAT THE LINOTYPE IS

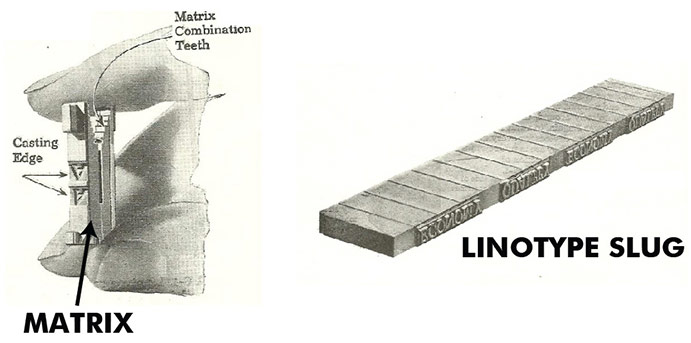

The Linotype is not a type-setting machine. No types are used in it. It composes with matrices - small brass units having characters indented in the egdes - hence the name “matrix”. These matrices are assembled into justified lines. From the matrix line the Linotype automatically casts a solid bar, or line, of type. This bar is known as the Linotype slug. It is ready for use when it leaves the machine.

THE LINOTYPE HAS FOUR MAJOR DIVISIONS:

1. The Magazines which contain the matrices. - They represent type cases. Beacuse every matrix ciculates automatically back to its place in the magazine as soon as it has served in a line of composition, a font of matrices is small in number compared with a font of type. A magazine is so compact and light that the operator can handle it without exertion, and can produce a variety of composition by simply changin magazines.

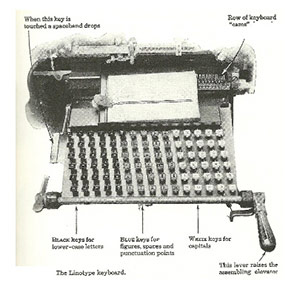

2. The Keyboard and its related parts. - This controls the release of the matrices from the magazine in the order in which the characters are desired. The Linotype operator, from his seat at the keyboard, has complete control of every function of the machine. His duties are limited merely to operating the keyboard keys - justification and distribution are mechanically automatic.

3. The Casting Mechanism - This division of the machine makes the Linotype-equipped printer his own type-founder. The justified line of matrices is presented automatically to the casting mechanism, molten type-metal is forcee into the indented characters on the edges of the matrices, and the cast line, a single unit with a new type-face, is delivered to the gallery on the machine, precisely trimmed and ready to go into the form.

4. The Distributing Mechanism. - When a line of matrices has served for casting the line of type, it is lifted automatically and carried to the top of the magazines, where, by a simple though ingenious system, each matrix is delivered to its proper place in the magazine, and is ready to serve again. Thus in the Linotype-equipped shop there is no distribution of type.